Prioritizing Safety: Preventing Forklift Accidents

At The Austin Company, safety is woven into every aspect of our operations. When it comes to using forklifts, we understand the critical importance of adhering to strict safety protocols to ensure the well-being of our team members and clients. Forklifts are invaluable tools for raising, lowering, and transporting materials efficiently, but they also come with inherent risks. That’s why we’ve implemented comprehensive measures to minimize the potential for accidents and injuries.

Comprehensive Training

Proper training is non-negotiable when it comes to forklift operations. Our team members undergo training, certification, and authorization processes before they are allowed to operate a forklift. We emphasize the importance of experience and proficiency, ensuring our operators are fully equipped to handle forklifts safely.

Pre-shift Inspections

Before each use, our forklift operators conduct thorough pre-shift inspections to identify any potential issues or hazards. From checking for visible damage to ensuring all controls are functioning correctly, these inspections maintain the integrity and safety of the equipment.

Prioritizing Nearby Workers’ Safety

We recognize the importance of maintaining awareness of nearby workers while operating a forklift. Our operators are trained to sound the horn when approaching blind corners or congested areas and continuously maintain a safe distance from crew members.

Adhering to Load Limits

Ignoring load limits is a common cause of tip-overs. Respecting a forklift’s load capacity can prevent accidents. Our team members are trained to understand and never exceed the equipment’s limits.

Ensuring Load Security

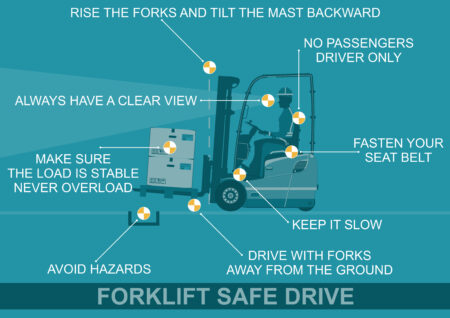

Properly securing and balancing loads is necessary for safe forklift operation. We emphasize the importance of evenly distributing weight on the forks and tilting them back slightly to stabilize the load, ensuring that loads are positioned and secured correctly.

Clear Communication

Effective communication is key to preventing accidents in a busy work environment. Our team members use hand signals, horns, and radios to communicate with each other and to alert others of their presence. We establish clear pathways and designated zones for forklift operations to minimize the risk of collisions.

Driving Safely

Our operators prioritize safety over speed when operating forklifts. They avoid high speeds and sharp turns, instead opting for smooth, controlled maneuvers to keep the forklift and its load stable. Additionally, they maintain a safe distance from the edges and drive cautiously on grades to prevent accidents.

Heightened Awareness

We instill a culture of vigilance among our team members, encouraging them always to be mindful of overhead obstructions such as power lines, pipes, and signs. Keeping the load as low as possible helps mitigate the risk of contact with overhead obstacles.

At Austin, safety isn’t just a checkbox; it’s a fundamental aspect of everything we do. By providing rigorous training, conducting meticulous inspections, communicating clearly, and being prudent in our operations, we minimize the risk of forklift accidents and ensure a safe working environment for everyone. To learn more about Austin’s safety and quality assurance program.

|

Craig HerndonSafety ManagerCall 219.309.8985| Email Craig| View Profile |