A Retrospective of the First 100 Years of Work Completed by Austin’s California Office

This is the third in a series of monthly articles chronicling highlights of the first 100 years for The Austin Company’s California office. Last month in the 1930s Austin California entered the field of aviation with the Burbank Airport followed by NBC’s Radio City West in Hollywood. This month we look at the 1940s, touching on Austin’s nationwide projects supporting the WWII war efforts, and follow with, the new era of television.

The Austin Company Supports the WWII War Efforts and the Birth of Television

World War II (September 1, 1939, to September 2, 1945)

Austin spent much of the first half of the 1940s focused on the war effort with its California office supporting projects in the areas of shipbuilding, aircraft assembly, machine tool factories, electronic instruments, and devices, as well as two major penicillin plants, among others.

In 1939, the outbreak of war in Europe resulted in a large-scale expansion of America’s aviation industries. Just 22 years earlier, during WW1, Austin had built the world’s largest aircraft plant and had pioneered the design of aircraft hangars, wind tunnels, dirigible mooring masts, and airports. This experience, coupled with Austin’s know-how gained by developing the first controlled conditions (air-conditioned) factory, positioned Austin as the nation’s largest builder of military aircraft assembly plants. These particular assembly plants needed the “blackout” protection that a controlled conditions buildings could provide. An impressive list of major aircraft assembly projects was completed between 1939 and 1943 in the Pacific Northwest, Chicago, Fort Worth, Niagara Falls, Oklahoma City, Tulsa, and Wichita, among other locations.

Television

As Austin passed the peak of its wartime activity in 1943, the company shifted some of its focus for the change in construction that would eventually come with the end of the war. It was believed that there was a large amount of capital and technology that was waiting to be applied in peacetime. This would result in new products and companies. Austin prepared to be ready for these changes.

One area of change was television. “Electronic television” was first successfully demonstrated in San Francisco in September of 1927, but it was not until the 1939 World’s Fair in New York (April 30, 1939 – October 27, 1940) – as the war was breaking out in Europe – that the first practical TV sets were sold to the public. Although television sets had been available as early as the late 1930s, the widespread distribution and sale of TV sets did not take off until after the war, and Austin was ready to support the new industry’s development of shows to broadcast.

Austin was convinced that the end of the war would bring the American consumer increased leisure time, and television would be a major growth industry in the postwar era. (Some business leaders believed that no medium could ever displace the dominance of radio.) Nonetheless, Austin developed a television studio construction program two years before the end of the war. Austin went all-in on its belief that returning GIs would be all too happy to spend time in the coming years in front of the TV set with their families. Austin unveiled its working model of a television network studio in April 1944.

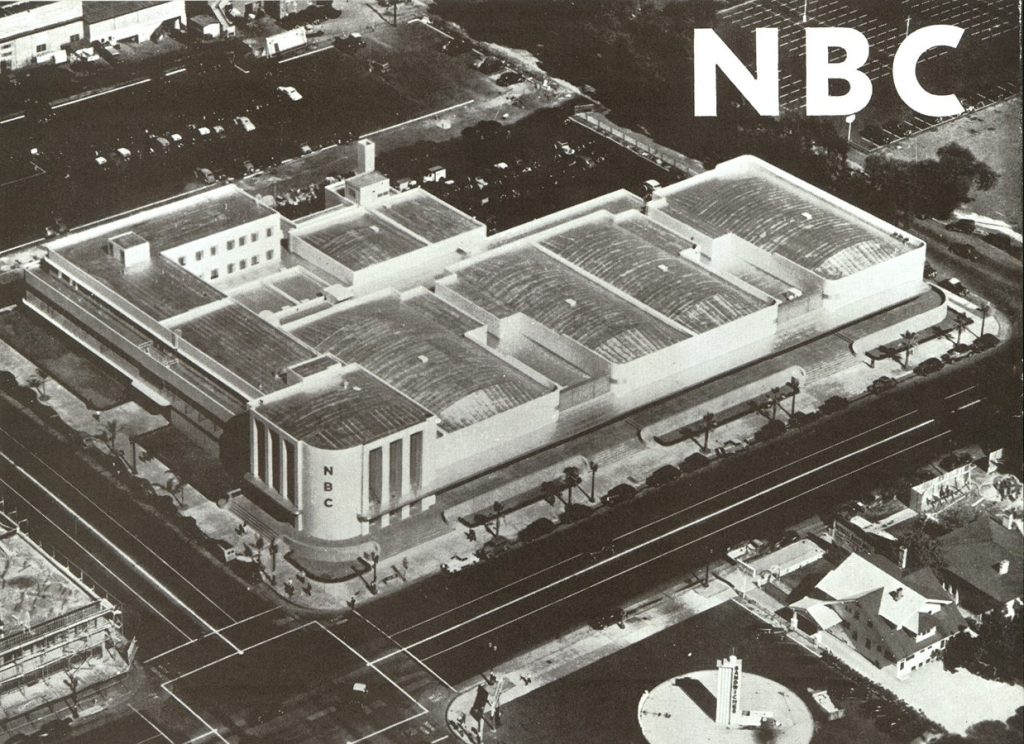

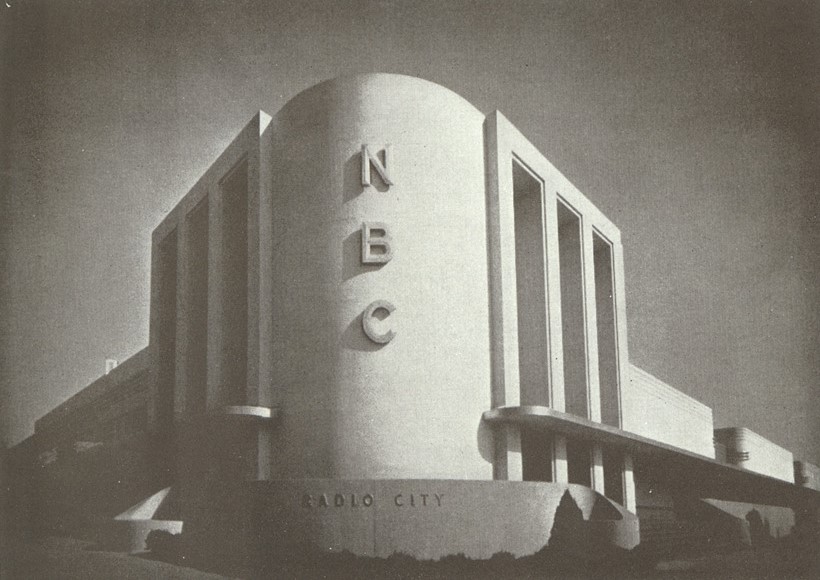

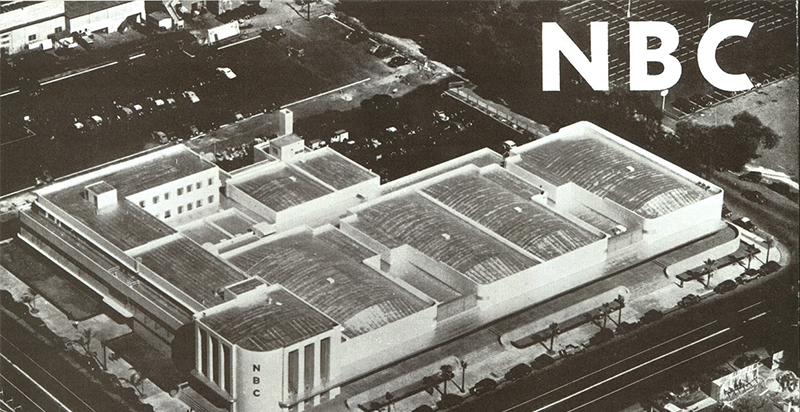

In 1938, Austin completed the design and construction of NBC’s Radio City West in Hollywood. (See the 1930s article published in March.) After only a few short years, however, television was ready for widespread availability to the public, and Austin was there to convert Radio City West to television.

Over a series of projects beginning in 1944, Austin implemented the changes necessary for the larger radio studios, including audiences and television cameras (black and white at the time), and state-of-the-art television broadcasting equipment. Changes in technology meant significantly increased lighting, structural upgrades to support the lighting, and added air conditioning to accommodate the increased heat load from the lights, along with larger control rooms than were required for radio.

Join us next month as we discuss the 1950s when NBC would outgrow the Radio City West facilities in Hollywood. A new site in Burbank would be purchased to become the West Coast home of NBC Television.