REFRIGERATION

- High Pressure and Temperature Piping Systems.

- Modularization of Major Piping Systems.

- Refrigeration System and Conversions.

- 3D System Design Platforms.

- PSM to Satisfy OSHA 191D for Large NH3 Piping Systems, Including Pipe Stress Analysis.

- Design of Freezer Systems and Vapor Barrier.

WASTEWATER TREATMENT

- Flow Equalization.

- Stream Segregation to Treat Wastes.

- Segregation of Storm Systems.

- pH Adjustment of CIP System Discharges and Production Waste.

- Oil and Grease Removal from Waste.

- Solids Removal, Screens, Clarifiers, Thickeners, Filtration, and Multiple Types of Dewatering systems.

- Precipitation for Conversion of Dissolved Solids.

PACKAGING CONSIDERATIONS

- Integrated Team Works to Address Critical Packaging System(s) Considerations.

- Concept Definition and Feasibility.

- Scope and Functional Requirements Documentation.

- Detailed Design.

- Equipment Selection Assistance and Procurement.

- Construction, Installation, Commissioning, and Start-Up.

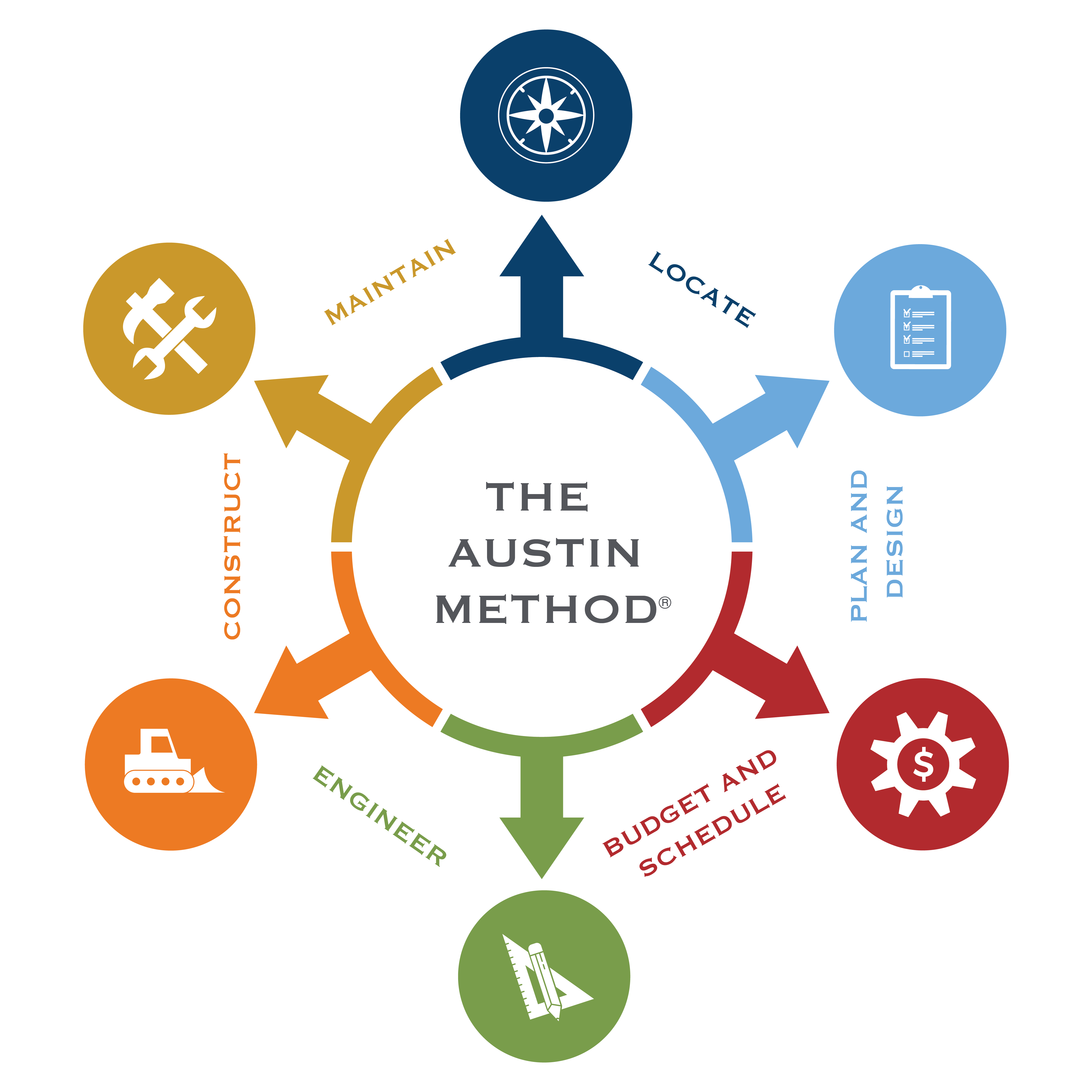

THE AUSTIN METHOD®

The Austin Method is the proprietary design-build method developed in 1901 to provide clients a single-source for the design, engineering, and construction of a project. Austin can provide services from start to finish—or any step in between—to meet the client’s objectives for a project on time and within budget.

Austin offers multiple approaches in implementing a project. These generally can be classified into either a design-bid-construct or design-build project approach. In addition, Austin offers The Austin Method, which applies stringent project controls and combines the advantages of “design-bid construct” and “design-build” approaches into a competitive bid, cost-effective, and accelerated-schedule project implementation.

TO LEARN MORE ABOUT OUR BEVERAGE PROJECTS, VIEW OUR PROJECT GALLERY